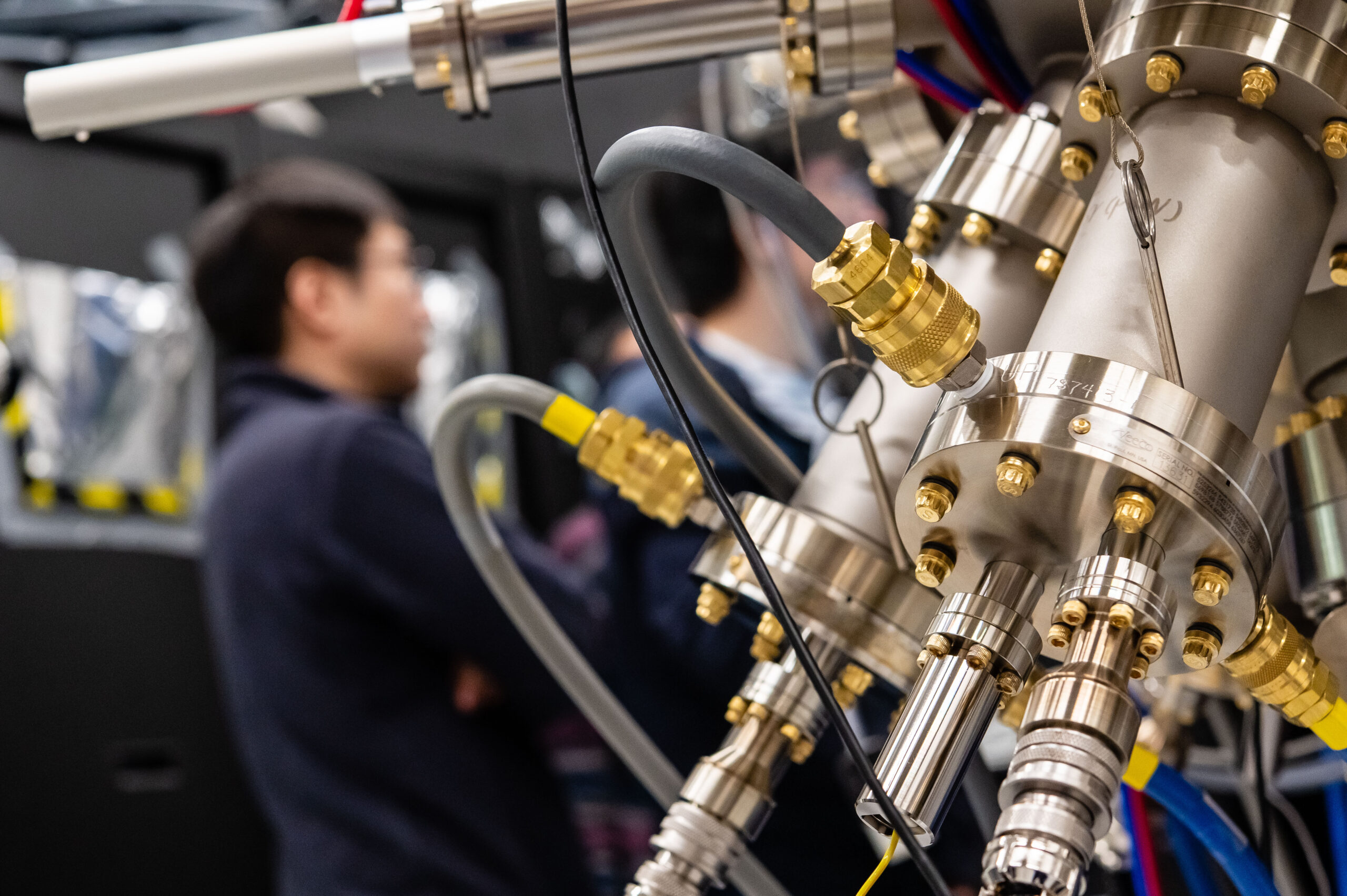

Custom tools developed in-house at the Blusson QMI machine shops

Blusson QMI is home to two machine shops: a Computer Numerical Control (CNC) shop and student machine shop (Room 125) and a high-head prototype machine shop (Room 124B). These are important facilities for the institute, offering support to researchers by enabling them to participate in the development of custom mechanical, ultra-high- vacuum and cryogenic equipment.

The Machine Shop team works with our researchers, staff, and students to design, prototype and manufacture components for ultra-high-vacuum and cryogenic equipment to be installed on various Blusson QMI and AMPEL research equipment.

Activities include:

- performing general and computer numerical control (CNC) machining

- fabrication and assembly of specified vacuum, cryogenics, and mechanical components and devices

The team also plans and complete custom jobs, developing supportive tools and components for specialized research equipment for unique applications. In most cases, these are novel parts that are not commercially available.

Accessing the machine shop

Students, research associates, and faculty are invited to submit their machining requirements to Harish Gautam by email to hgautam@phas.ubc.ca; accepted formats include 2D (PDF format) and 3D drawings (STEP format) including hand sketches via email.

For more information, including a list of tools that are currently available and machine shop hours are available at the Advanced Materials and Process Engineering Laboratory (AMPEL) website.

Training for graduate students

A feature of the Blusson QMI machine shops is the ability for students to learn machining skills under the supervision of shop technicians. For more information, email Harish Gautam, Machine Shop Supervisor, at hgautam@phas.ubc.ca.