[MEDIA RELEASE]

A groundbreaking technique that produces high-quality and large-area two-dimensional (2D) materials inside a protected environment could open up new avenues for exploiting the materials’ electronic properties. An international team of material scientists, including researchers from UBC Blusson QMI, unveiled the technique in Advanced Science this week.

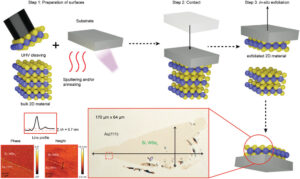

Dubbed Kinetic In-situ Single-layer Synthesis (KISS), the technique involves bringing the bulk sample of a layered material in contact with a substrate such as gold or silver directly inside a vacuum.

“This enables in-situ exfoliation of 2D materials, yielding large, high-quality samples devoid of contaminants and impurities,” said Dr. Matteo Michiardi from Blusson QMI, who has been working on the study with colleagues from KTH Royal Institute of Technology in Sweden, the University of Groningen in the Netherlands, and the Aarhus University in Denmark.

Image: Schematics of the KISS technique: Layered material and substrates are prepared in vacuum environment and gently approached to create large flakes of 2D materials.

“Our results can provide a new platform to study a wide variety of new systems that have so far been elusive, such as the superconductivity in two dimensions, the quantum spin Hall effect or the burgeoning field of 2D magnetism.

“The method is remarkably simple, requiring only the equipment commonly found in a typical surface science laboratory, making it easily accessible and straightforward for surface science labs worldwide.”

Since graphene—a single layer of graphite that exhibits outstanding physical properties that do not exist in its bulk form— was discovered in 2004, the field of 2D materials research has expanded rapidly.

The most commonly used methods to produce 2D materials to date were chemical vapour deposition, molecular beam epitaxy (MBE), and mechanical exfoliation, which present major drawbacks.

With chemical vapour deposition and molecular beam epitaxy (MBE), which involve evaporating the elements onto a substrate, researchers face complexities such as defining new stable growth recipes, selecting appropriate substrates, and working on samples that are not well-ordered.

Mechanical exfoliation is carried out using adhesive tape to lift flakes from the material’s bulk form and then transfer them to a vacuum. This results in exfoliated 2D flakes that are small and susceptible to contamination, with the latter being especially problematic for air-sensitive samples.

Using the KISS method, the contamination problem is eliminated as the material is produced inside a vacuum from the start.

“Gold or silver substrates work particularly well with the KISS method. Once cleaned through standard vacuum techniques, they show dangling chemical bonds that stick out of their surface. The affinity of the bulk exfoliative materials to these dangling bonds is really high, which means that the sample tends to stick more to the substrate than to the bulk of itself,” Dr. Michiardi said.

The quality of the samples produced using KISS was verified with several surface-sensitive techniques, including Angle-Resolved Photoemission Spectroscopy (ARPES).

“ARPES is an in-vacuum technique we are very familiar with here at Blusson QMI. ARPES allows us to produce an image of the flake and map the electronic structure of the sample, which is what researchers around the world are very interested in,” Dr. Michiardi noted. “Indeed, the KISS technique has already been widely adopted here at Blusson QMI, yielding important primary results.”

Notably, the ARPES data presented in the study were obtained using two experimental setups with macroscopic beam footprint, in contrast to typical ARPES measurements on exfoliated flakes that require microfocusing capabilities, which are available only in a handful of facilities in the world, including Blusson QMI.

To view the publication in Advanced Science, please click here.

To learn more about Blusson QMI research capabilities and facilities, please see here.

#ENDS#

Media contact: Shahrzad (Zad) Abbasi | 604 360 6761 | shahrzad.abbasi@ubc.ca