Nanofabrication Accelerator Program

Expressions of interest are now open for the second round of UBC Blusson QMI’s Nanofabrication Accelerator Program in partnership with the National Research Council of Canada Industrial Research Assistance Program (NRC-IRAP), Innovation UBC, and the Creative Destruction Lab-Vancouver.

The program will provide eligible small or medium-sized businesses (SMEs) with specialized nanofabrication services, including but not limited to:

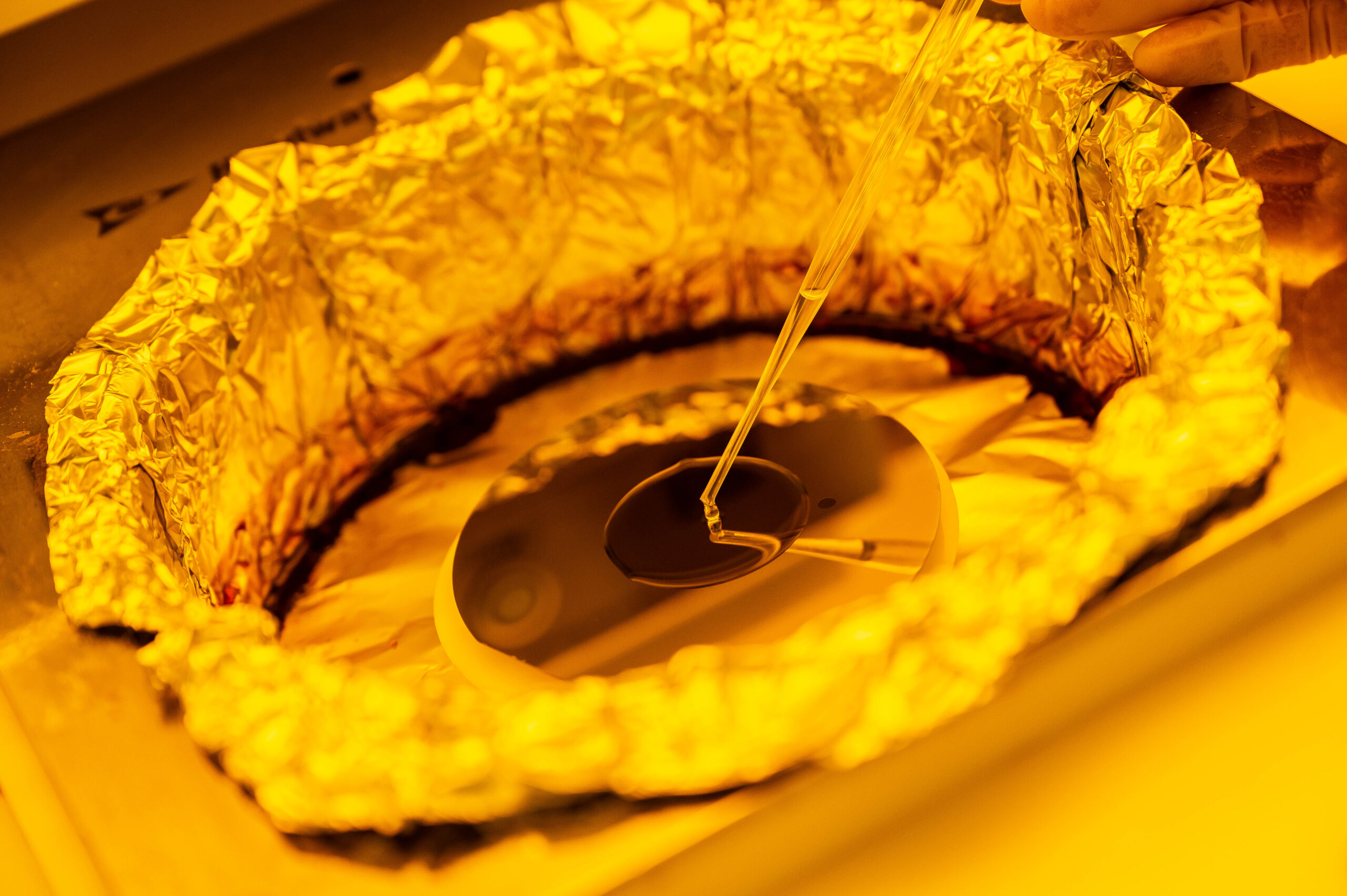

- Maskless photolithography

- 100kV electron-beam lithography

- Photonic wire-bonding

- Thin film deposition and etching processes

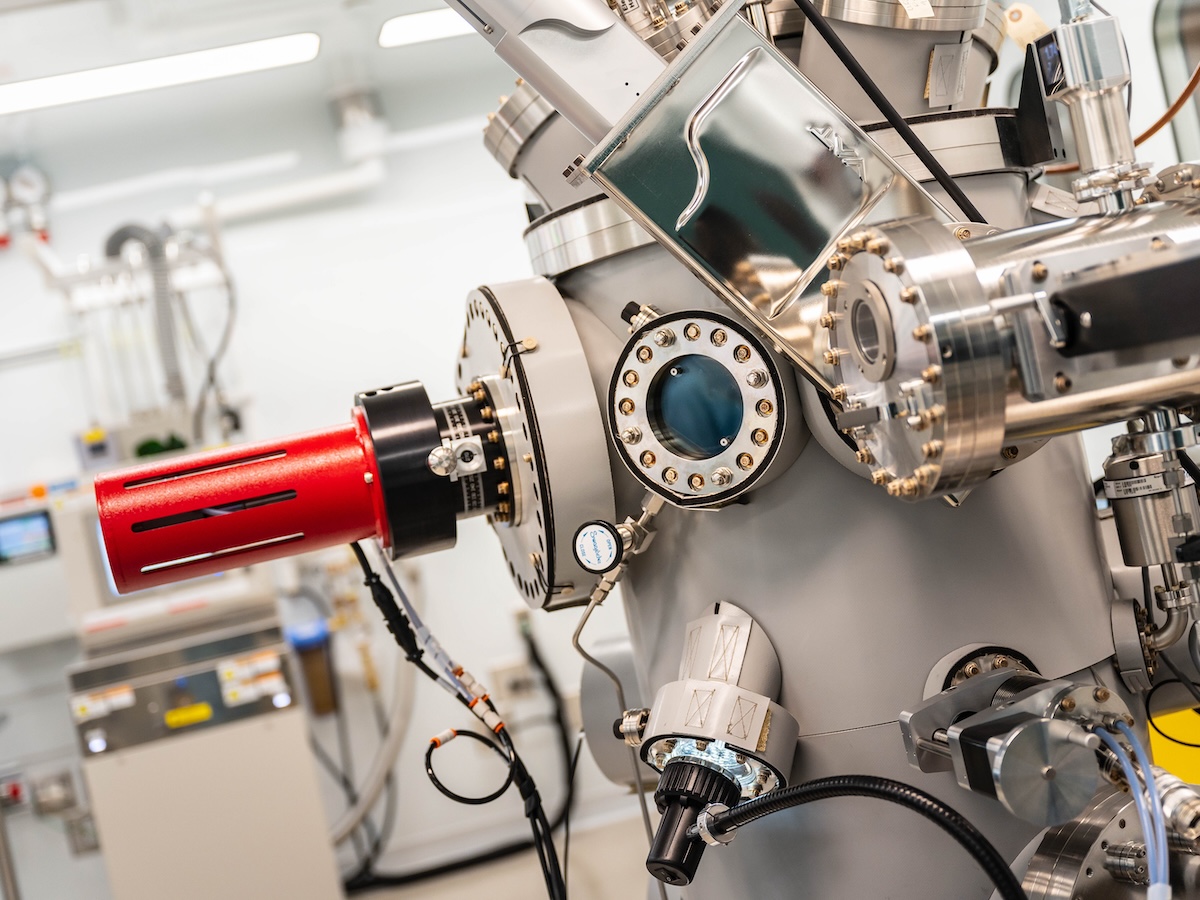

Companies will have access to recently upgraded cleanrooms. Services will be offered on a per-usage fee basis, including SME staff training for using the various tools and professional assistance from the facility’s technical staff. Up to $18,000 of funding is available per SME project, each of which will be limited to a maximum of 6 months in duration.

Expertise & Industry Applications

As part of UBC Blusson QMI, ANF partners have access to 25 multidisciplinary teams of physicists, chemists and engineers with expertise in areas including but not limited to materials synthesis, quantum sensing, clean energy, quantum algorithms, and quantum computation.

Current industry clients use the ANF for design, hybrid integration and testing of silicon photonic chips for applications in quantum computing, quantum networking, biomedical sensing, automotive LiDar and data communications.

Program Timeline

The program is scheduled to run until September 2025 and can accommodate only a limited number of projects.

How to Apply

SMEs interested in taking advantage of our enhanced technical innovation capabilities for enabling faster technology deployment and commercialization in their relevant industrial sectors are therefore being called to submit an expression of interest by contacting UBC Blusson QMI Facilities Director Pinder Dosanjh at pinder.dosanjh@ubc.ca.